Optimize Your Supply Chain with Strategic Transloading

In today’s fast-paced logistics environment, getting products from port to market quickly and cost-effectively can make or break your competitive advantage. Transloading offers a powerful solution—a logistics strategy that transfers freight between different transportation modes to save time, reduce costs, and add flexibility to your supply chain.

At Precision Worldwide Logistics, our transloading facilities are strategically located less than 30 minutes from the Port of Los Angeles and Port of Long Beach, enabling faster container turnaround and significantly reduced transit times. Whether you’re importing consumer goods, manufacturing components, or distributing products across the West Coast, our near-port transloading services empower your business to be more agile and responsive in meeting customer demand.

What is Transloading? (Definition & Importance)

Transloading is the process of transferring cargo from one mode of transportation to another—for example, unloading goods from ocean containers or railcars and reloading them onto trucks for final delivery. Unlike traditional intermodal shipping, where freight remains in the same container throughout its journey, transloading involves physically handling and often re-palletizing cargo to optimize shipments for their next leg.

Why Transloading Matters

Transloading allows shippers to leverage the strengths of multiple transport modes—combining economical long-haul rail or ocean freight with the flexibility and speed of trucking—to optimize both the efficiency and costs of their supply chain. This capability is especially critical for:

- International shipments arriving at major ports like Los Angeles/Long Beach

- Cross-country distribution requiring different modes for different segments

- Time-sensitive freight that needs rapid port-to-market delivery

- Businesses seeking cost optimization through mode flexibility

For companies operating in Southern California’s import-export ecosystem, transloading provides the routing flexibility needed to reduce overall shipping costs while maintaining—or even improving—delivery speed.

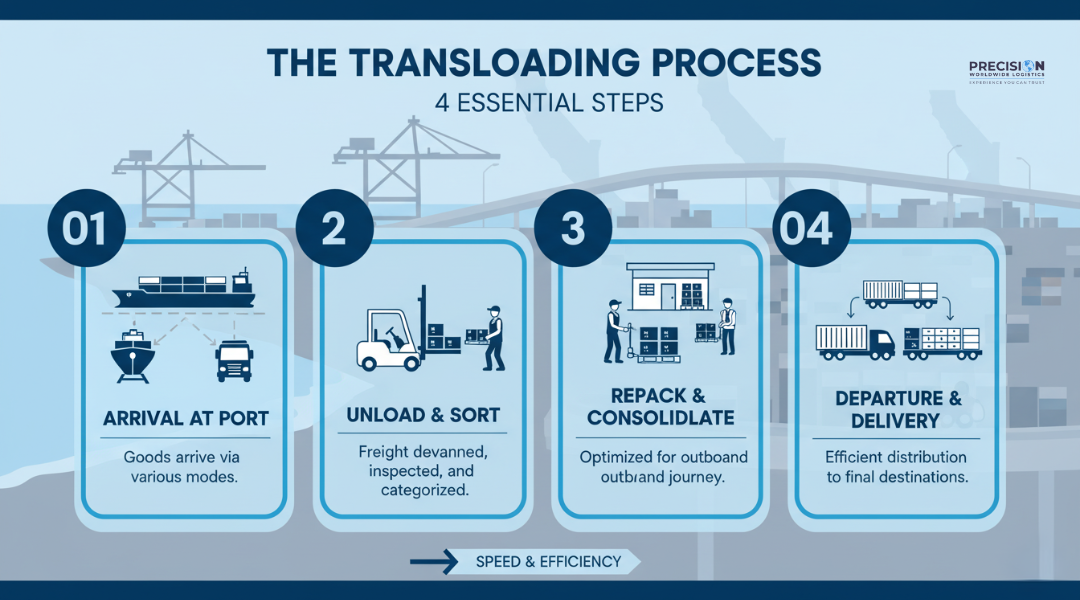

How the Transloading Process Works

Understanding the transloading workflow helps you see how this service accelerates your supply chain:

1. Inbound Arrival

Cargo arrives at our transload facility near the port via ship, rail, or incoming truck. Our strategic location means minimal drayage time from terminal to warehouse.

2. Unloading & Sorting

Shipments are efficiently unloaded from containers or trailers and sorted by destination, product type, or customer. A single inbound container can be split into multiple shipments destined for different locations—or multiple smaller shipments can be consolidated into full truckloads.

3. Repacking & Optimization

Goods are palletized or repackaged into configurations that maximize efficiency for the next transportation leg. This might mean breaking down bulk shipments into store-ready loads, combining partial loads to eliminate wasted truck space, or reconfiguring pallets for specific delivery requirements.

4. Outbound Transfer

Sorted and optimized freight is loaded onto outbound trucks or railcars to continue its journey to final destinations—whether that’s a distribution center, retail store, manufacturing facility, or end customer.

Speed is Critical

This entire process happens rapidly to avoid unnecessary storage. Freight typically spends minimal time at our facility—sometimes just hours—before moving out to its next destination. In Southern California’s congested port environment, this quick turnaround accelerates delivery timelines, frees containers for return to the port, and reduces terminal congestion.

Real-World Example: A container of apparel arrives at the Port of LA on Monday morning. By Monday afternoon, it’s at our La Mirada facility being sorted into store-specific shipments. By Tuesday morning, multiple truckloads are en route to retail distribution centers throughout California, Nevada, and Arizona—delivering products days faster than traditional warehousing would allow.

Key Benefits of Transloading

Faster Delivery & Reduced Transit Times

By combining transportation modes strategically and positioning inventory closer to end destinations, transloading reduces overall transit time from port to market. Your customers or downstream facilities receive goods faster—a critical advantage for time-sensitive freight, seasonal products, and just-in-time manufacturing.

Lower Transportation Costs

Transloading delivers real cost savings through multiple mechanisms:

- Mode optimization: Leverage low-cost rail for long-haul segments and trucks for final-mile flexibility

- Load consolidation: Combine partial shipments to eliminate half-empty trucks and reduce per-unit shipping costs

- Reduced storage fees: Goods move through facilities quickly rather than accumulating expensive storage days

- Avoided demurrage: Fast container turnaround prevents costly port detention charges

The combination of economical rail transport with flexible trucking gives you the best of both worlds—significant cost reduction without sacrificing delivery speed.

Flexibility to Adapt Transportation Modes

Market conditions change. Port congestion happens. Rail delays occur. Transloading offers the flexibility to easily switch between modes in response to changing costs, capacity constraints, or demand fluctuations. This agility adds resilience to your supply chain—if one mode experiences disruption, you have options to keep freight moving.

Wider Market Reach

With transloading, you’re not limited to destinations with direct port or rail access. Reach inland markets, multiple regional hubs, and remote locations by distributing freight into trucks at strategic transload points. One container can become several truckloads destined for different cities across the western United States—dramatically expanding your distribution capabilities from a single port entry point.

Optimized Inventory Management

Because transloading moves goods through facilities quickly rather than into long-term storage, companies can maintain leaner inventory levels at the port. This reduces warehousing needs and carrying costs—products spend less time idle and more time moving toward where they’ll be sold or used.

Reduced Port Congestion & Container Fees

Quickly clearing containers through transloading helps avoid clogging port terminals and incurring fees for extended dwell times. This keeps the entire supply chain fluid—essential at high-volume entry points like Los Angeles and Long Beach. Faster container returns also improve your standing with steamship lines and chassis providers.

Environmental Benefits

For sustainability-focused companies, transloading can contribute to reduced carbon emissions. Consolidating shipments into fewer, fuller trucks reduces fuel consumption per unit shipped. Utilizing rail for long distances before transloading to trucks for final delivery significantly lowers the environmental impact compared to long-haul trucking alone.

Transloading vs. Cross-Docking vs. Intermodal – What’s the Difference?

These logistics terms are often confused, but understanding the distinctions helps you choose the right solution for your supply chain needs.

Transloading vs. Cross-Docking

Cross-docking typically involves direct transfer of goods from inbound to outbound transportation on the same mode—usually truck-to-truck—with little or no storage in between. Freight often stays on its original pallets and simply moves from one dock door to another within a distribution center. Cross-docking excels at speeding retail goods through the supply chain with minimal handling.

Transloading involves changing transportation modes (ship-to-truck, rail-to-truck, or other combinations) and often includes breaking down, re-sorting, and re-packaging freight for optimization. While both minimize storage time, transloading specifically addresses the need to switch between different types of transportation equipment.

When to use cross-docking: Best for domestic distribution where speed matters more than mode flexibility—particularly in retail fulfillment operations.

When to use transloading: Best when leveraging multiple transport modes for cost efficiency and flexibility across longer distances—especially for international shipments or cross-country distribution.

Transloading vs. Intermodal

Intermodal shipping keeps cargo in the same container throughout its journey—the container or trailer itself transfers between truck, rail, and ship. The goods inside never leave the container.

Transloading physically moves goods from one container or conveyance into another. This offers more flexibility for consolidating partial loads, splitting shipments to multiple destinations, or repackaging freight—capabilities that intermodal’s container-stays-sealed approach doesn’t provide.

When to use intermodal: When your shipment can stay intact from origin to final destination and the container size matches your needs throughout the journey.

When to use transloading: When you need to optimize loads, split shipments, combine freight from multiple sources, or adapt to different equipment requirements across transportation segments.

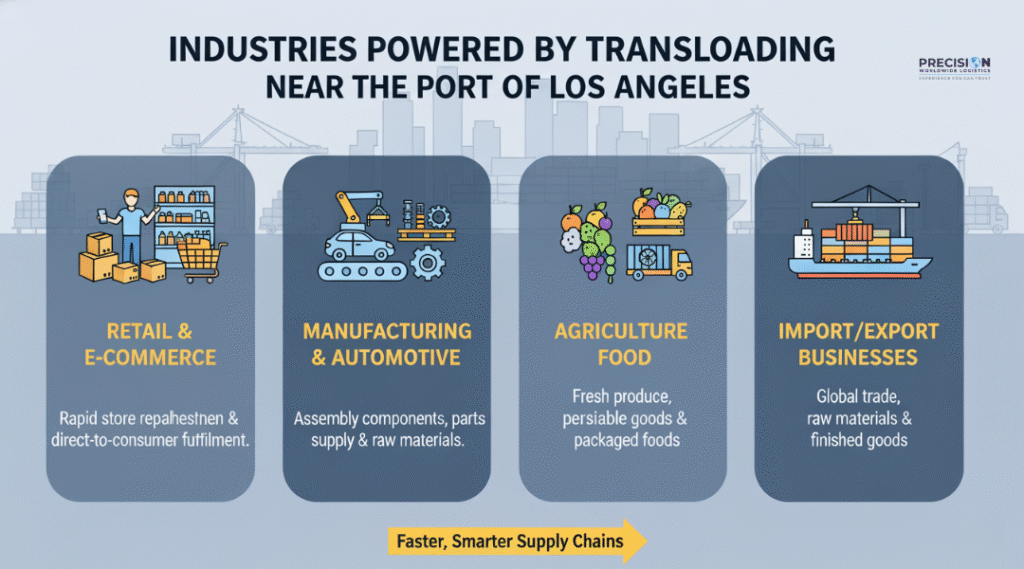

Industries & Use Cases Suited for Transloading

Retail & E-Commerce

High-volume consumer goods arriving through West Coast ports benefit enormously from transloading. Large retailers use this service to break bulk shipments into store-ready loads, enabling rapid replenishment cycles that keep shelves stocked. In the e-commerce era, where customer expectations for fast delivery continue rising, the speed and flexibility of transloading help meet demand without the delays of traditional warehousing.

Manufacturing & Automotive

Manufacturers importing components, raw materials, or finished products rely on transloading to maintain just-in-time delivery schedules. For the automotive industry specifically, heavy or oversized parts arriving by rail or ship can be transloaded to specialized trucks for final delivery to assembly plants—ensuring production lines never stop due to supply delays.

Agriculture & Food Products

Even perishable or seasonal agricultural goods benefit from transloading. Produce arriving in refrigerated containers can be quickly transloaded to temperature-controlled trucks for rapid distribution to markets, preserving freshness. Bulk commodities can switch modes at transload facilities for efficient inland transport, reducing spoilage risk and ensuring products reach consumers at peak quality.

Import/Export Businesses Serving Southern California

Any business bringing goods through Los Angeles or Long Beach ports gains a significant time-to-market advantage using nearby transloading services. By positioning transload operations close to port terminals, companies dramatically reduce the distance goods must travel between ships and final destinations, cutting both transit times and transportation costs. This proximity advantage is especially valuable for businesses serving West Coast markets or distributing throughout the western United States.

Example Use Case: An electronics importer receives multiple smaller container shipments from various Asian suppliers. Through transloading, these are combined into optimized full truckloads bound for specific West Coast cities—Seattle, San Francisco, Phoenix, and Las Vegas. This consolidation reduces per-unit shipping costs by 30% while actually speeding delivery by eliminating intermediate warehouse stops.

Precision Worldwide’s Transloading Capabilities

Strategic Location Near LA/Long Beach Ports

Our La Mirada facility sits less than 30 minutes from the Port of Los Angeles and Port of Long Beach—the busiest port complex in North America. This proximity translates directly into faster port pickups, quicker container turnaround, and reduced drayage costs for our clients. We deliver on the promise of true port-centric logistics, minimizing every minute between vessel discharge and outbound transport.

Asset-Based Operations for Reliability

Unlike many competitors, Precision Worldwide Logistics is an asset-based 3PL—we own our fleet of trucks, chassis, and equipment. This matters because you’re not dependent on external drayage brokers or the notoriously tight chassis pool at LA/Long Beach ports. Common failure points in port logistics—waiting for third-party availability, equipment shortages, scheduling conflicts—simply don’t affect our operations the same way. We guarantee reliability and maintain complete control from ship to final truck.

State-of-the-Art Transload Facilities

Our warehouse facilities are specifically designed for high-throughput transloading operations:

- Multiple loading docks for simultaneous inbound/outbound operations

- Full complement of material handling equipment (forklifts, pallet jacks, dock plates)

- Capacity for diverse cargo types from standard palletized goods to oversized machinery

- 24/7 surveillance and secured gated yards for cargo security during transfer

- Climate-controlled options for temperature-sensitive freight

25+ Years of Experience & Handling Expertise

Our trained staff and logistics experts bring more than a quarter-century of port operations experience to every transload. We understand that the additional handling steps in transloading create concern about potential damage—our track record speaks to our commitment to safe, damage-free transfers with meticulous attention to detail. We adhere to strict safety protocols and compliance standards, protecting your freight and meeting all regulatory requirements.

Integrated One-Stop Logistics

Precision offers comprehensive supply chain solutions beyond transloading:

- Short-term storage: Hold inventory briefly if final destinations aren’t ready to receive

- Inventory management: Real-time tracking and reporting of goods in our facility

- Order fulfillment: Pick, pack, and ship services for e-commerce and retail clients

- Over-the-road trucking: Seamless onward transportation to any U.S. destination

- Drayage services: Direct port-to-facility container delivery with our owned equipment

This integrated approach means clients solve multiple supply chain challenges with a single trusted partner. Cargo can be transloaded, held as inventory, then shipped on-demand—providing flexibility when market conditions or customer requirements change.

Technology-Driven Visibility

Our technology systems provide transparency at every transloading step:

- Barcode scanning for accurate tracking from receiving through shipping

- Real-time shipment status updates accessible to clients 24/7

- Inventory management systems that integrate with your existing supply chain software

- Automated alerts for exceptions or delays

- Digital documentation and proof of delivery

This data-driven approach minimizes errors, keeps customers informed, and provides the visibility that modern supply chains demand.

Value-Added Services

We go beyond basic freight transfer:

- Quality inspections to identify damage before goods enter your supply chain

- Repalletizing to optimize for downstream handling

- Labeling and marking services to meet retailer compliance requirements

- Shrink-wrapping and load securing for safe transport

- Sorting by SKU, destination, or any other specification

Scalability & Flexibility

Our asset-based infrastructure and experienced team accommodate volume surges or last-minute changes without missing a beat. If a shipment’s destination changes while the vessel is en route, Precision can transload and reroute accordingly. Need to scale up capacity during peak season? We have the equipment and staffing flexibility to handle it. This agility is exactly what logistics managers in Southern California need when operating in dynamic market conditions.

Why Choose Precision for Transloading in Los Angeles?

✓ Proven Expertise: Over 25 years serving the LA port logistics market means we have deep understanding of port operations, carrier requirements, and transloading best practices. Your freight benefits from hard-earned experience that prevents costly hiccups.

✓ Location Advantage: Near-port warehouses for Los Angeles/Long Beach ensure the fastest possible transfer from ship to truck, cutting inland transit time and reducing wait times that plague more distant facilities.

✓ Asset-Based Reliability: Our owned trucks, chassis, and equipment guarantee availability and responsive service. You’re never left waiting on third-party resources, improving your ability to meet delivery deadlines.

✓ Comprehensive Solutions: Integrated services under one roof—transloading plus drayage, warehousing, and distribution. Simplify vendor relationships and get seamless end-to-end logistics from port pickup to final delivery.

✓ Customized Approach: Tailored transloading plans designed around your specific cargo and schedule. Our customer-centric philosophy means dedicated support and high-touch communication throughout the process.

✓ Efficiency & Cost Savings: Our streamlined processes deliver quick container turnaround (avoiding storage fees and demurrage) while optimizing your transportation mode mix for maximum savings.

✓ Safety & Compliance Focus: Industry-leading safety standards govern every transload operation. Our secured facility and trained team reduce risk of loss or damage, providing peace of mind for your valuable shipments.

✓ Sustainability Practices: We implement eco-friendly practices including route optimization to reduce fuel consumption, contributing to your company’s sustainability goals while cutting costs.

Request a Transloading Quote Today

Ready to streamline your supply chain with expert transloading services near the Port of Los Angeles?

Contact Precision Worldwide Logistics today for a customized solution.

Our logistics experts are standing by to design a transloading plan tailored to your specific needs—whether you’re importing retail goods, manufacturing components, or distributing products throughout the western United States. Let’s move your freight more efficiently.

Call: (800) 937-1599

Email: [email protected]

We respond to inquiries within hours, not days. Get started with a no-obligation consultation and discover how near-port transloading can transform your supply chain performance.

Frequently Asked Questions about Transloading

Q: What is transloading in logistics?

A: Transloading is the process of moving goods from one mode of transport to another—for example, transferring cargo from a ship or train onto trucks. It’s used to improve efficiency when a single journey involves multiple transportation methods, allowing companies to leverage the cost and speed advantages of different modes.

Q: How does transloading differ from cross-docking?

A: While both aim to minimize storage time, transloading involves switching transport modes (often ship-to-truck or rail-to-truck) and frequently includes repacking freight for optimization. Cross-docking typically transfers goods directly between trucks with minimal handling, keeping them on the same pallets. Transloading is common for international shipments, while cross-docking accelerates domestic distribution.

Q: What are the benefits of transloading near the Port of LA?

A: Transloading close to Los Angeles/Long Beach ports significantly cuts transit times and drayage costs. Cargo is quickly moved off the port, sorted, and dispatched to final destinations without lengthy storage periods. This helps businesses respond faster to demand, avoid port congestion fees, and reduce overall supply chain costs.

Q: How quickly can cargo be transloaded?

A: With Precision’s efficient operations, cargo can often be transloaded within the same day it arrives at our facility—sometimes in just a few hours. Speed depends on volume and complexity, but our goal is always to minimize dwell time and get freight moving to its next destination as quickly as possible.

Q: Can Precision handle special cargo or large volumes?

A: Yes. Precision Worldwide Logistics has versatile equipment and a skilled team capable of handling diverse cargo types—from standard palletized goods to oversized machinery and specialized freight. We manage both small shipments and large volumes, scaling our operations to meet your needs while ensuring safe, efficient handling.

Q: Do you offer storage if we’re not ready to receive freight immediately?

A: Absolutely. While transloading focuses on rapid transfer, we offer flexible short-term storage options if your downstream operations need time to prepare. Our integrated warehousing services mean freight can be held securely until you’re ready for delivery—adding another layer of flexibility to your supply chain.

Q: How does pricing work for transloading services?

A: Pricing depends on several factors including cargo type, volume, handling requirements, and any value-added services needed (repalletizing, labeling, etc.). Contact us for a customized quote based on your specific requirements. We’re committed to transparent pricing with no hidden fees.

Q: What geographic area do you serve for outbound delivery after transloading?

A: While our transloading facilities are located in Southern California, our trucking network serves the entire continental United States. We can transload your freight and deliver it anywhere in the country, making us ideal for companies using West Coast ports to serve national markets.

Precision Worldwide Logistics – Your Partner in Efficient Port-Centric Logistics